AMSOIL Synthetic Gear Lube Outperforms Valvoline Gear Lube

High quality gear oils must lubricate, cool and protect geared systems. They must also carry damaging wear debris

away from contact zones and muffle the sound of gear operation. Commonly used in differential gears and standard

transmission applications in commercial and passenger vehicles, as well as a variety of industrial machinery,

gear oils must offer extreme temperature and pressure protection in order to prevent wear, pitting, spalling,

scoring, scuffing and other types of damage that result in equipment failure and downtime. Protection against

oxidation, thermal degradation, rust, copper corrosion and foaming is also important.

High quality gear oils must lubricate, cool and protect geared systems. They must also carry damaging wear debris

away from contact zones and muffle the sound of gear operation. Commonly used in differential gears and standard

transmission applications in commercial and passenger vehicles, as well as a variety of industrial machinery,

gear oils must offer extreme temperature and pressure protection in order to prevent wear, pitting, spalling,

scoring, scuffing and other types of damage that result in equipment failure and downtime. Protection against

oxidation, thermal degradation, rust, copper corrosion and foaming is also important.

AMSOIL submitted its 75W-90 Synthetic Gear Lube (AGR) (replaced by AMSOIL Long Life Synthetic Gear Lube SAE 75W-90 [FGR])

and Valvoline 75W-90 Gear Lube to an independent laboratory for quality comparison tests. The gear lubes were tested according

to ASTM testing procedures in several critical performance areas, including oxidation resistance, viscosity retention and

cold temperature fluidity. Oxidation resistance was measured using the L-60-1 Thermal Oxidation Stability Test, viscosity

retention was measured using the KRL Shear Stability Test and cold temperature fluidity was measured using the Brookfield

Viscosity Test. Additional load carrying, wear, extreme pressure and scoring protection tests were performed exclusively on

AMSOIL 75W-90 Synthetic Gear Lube using the L-37 High Torque Axle Test and the L-42 High Speed Axle Test.

L-60-1 Thermal Oxidation Stability Test

Test Conditions

The L-60-1 Thermal Oxidation Stability Test measures a lubricant's rate of deterioration under severe oxidation

conditions. A measured sample of test lubricant is placed in a special gear case with two spur gears and a copper

catalyst strip. The gears are driven at 1,725 rpm at 163°C for a 50-hour duration, while air is bubbled

through the sample.

Viscosity increase, deposits not soluble in pentane or toluene, carbon varnish and sludge deposits are measured

upon test completion. Test specifications are listed below.

L-60-1 Thermal

Oxidation Stability Test Specifications |

|||

| API GL-5 | API MT-1/SAE J-2360/ MIL-PRF-2105E/Mack GO-J |

Mack GO-J+ | |

| Test Conditions | 50 hours @ 163°C | 50 hours @ 163°C | 100 hours @ 163°C |

| Viscosity Rise, % | 100 Max. | 100 Max. | 100 Max. |

| Pentane Insolubles, % | 3 Max. | 3 Max. | 3 Max. |

| Toluene Insolubles, % | 2 Max. | 2 Max. | 2 Max. |

| Carbon Varnish, rating | Not required | 7.5 Min. | 7.5 Min. |

| Sludge, rating | Not required | 9.4 Min. | 9.4 Min. |

L-60-1 Thermal

Oxidation Stability Test Results |

|||

| AMSOIL Synthetic 75W-90 |

Valvoline 75W-90 |

Valvoline 75W-90 |

|

| Test Conditions | 100 hours @ 163°C | 50 hours @ 163°C | 100 hours @ 163°C |

| Viscosity Rise, % | 25.17 | 17.50 | 38.50 |

| Pentane Insolubles, % | 0.20 | 0.87 | 1.17 |

| Toluene Insolubles, % | 0.13 | 1.11 | 0.99 |

| Carbon Varnish, rating | 8.0 | 7.2 | 5.9 |

| Sludge, rating | 9.5 | 9.4 | 9.4 |

Test Results

Because AMSOIL 75W-90 Synthetic Gear Lube is a premium lubricant designed for extended drain service, the test

was allowed to continue for 100 straight hours, double the standard test length. The Valvoline 75W-90 was run at

both the standard 50-hour test length and the double 100-hour test length. Test results indicate AMSOIL 75W-90

Synthetic Gear Lube outperformed Valvoline at both test lengths.

Even at double the standard test length, AMSOIL 75W-90 scored almost four times better than industry test

specifications in the area of viscosity increase, while also greatly exceeding specifications in all areas of the

test.

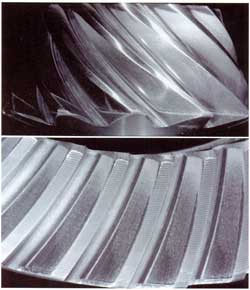

The photographs below show the superior deposit-control characteristics of AMSOIL 75W-90 Synthetic Gear Lube.

| L-60-1 Thermal Oxidation Stability Test Results | ||

| AMSOIL 75W-90 (100 hours) | Valvoline 75W-90 (100 hours) | Valvoline 75W-90 (50 hours) |

|

||

| Even after enduring a double-length, 100-hour L-60-1 Thermal Oxidation Stability Test, AMSOIL 75W-90 Synthetic Gear Lube produced significantly fewer deposits than the Valvoline 75W-90 run at a standard, 50-hour test. | ||

KRL Shear Stability Test

Test Conditions

It is essential that high-quality gear lubes resist shear to ensure adequate oil film thickness and protection against friction and wear. The KRL Shear Stability Test is used to determine the mechanical shear stability of lubricants containing polymer. Mandatory under the SAE J-306 gear oil standard, the KRL Shear Stability Test makes use of a taper roller bearing in order to shear the test fluid and determine the permanent drop in viscosity caused by the mechanical stress under practical conditions. Under the specifications of SAE J- 306, the measured viscosity at 100°C (212°F) of an SAE 90 gear oil must exceed 13.5 cSt after 20 hours of testing.

Test Results

AMSOIL 75W-90 Synthetic Gear Lube easily exceeded SAE J-306 specifications following the 20-hour test length

and was allowed to continue for a total of 192 straight hours, almost 10 times longer than the standard test

length. Even after this extended test, AMSOIL 75W-90 lost only 0.40 percent of its original viscosity, making it

99.6% shear stable.

Valvoline 75W-90 Gear Lube, on the other hand, failed the test during the initial 20-hour testing period, losing

14 percent of its original viscosity.

Brookfield Viscosity Test

Brookfield Viscosity Test

Test Conditions

The Brookfield Viscosity Test (ASTM 0-2983) is used to determine the internal fluid-friction of a lubricant during cold temperature operation. The lubricant sample is chilled in a -40°C (-40° F) air bath for 16 hours, and a Brookfield viscometer determines the torque required to shear the lubricant. The lower the cold temperature viscosity (measured in centipoise), the better the cold temperature protection. ASTM specifications dictate that 75W-90 gear oils measure less than 150,000 cP at test completion.

Test Results

AMSOIL 75W-90 Synthetic Gear Lube easily passed the Brookfield Viscosity Test, measuring 88,000 cP at test

completion, 42 percent less than test limits. The superior cold temperature properties of AMSOIL 75W-90 Synthetic

Gear Lube ensure quicker oil flow, enhanced component protection and improved fuel efficiency.

Many conventional lubricants fail to pass the Brookfield Viscosity Test due to the paraffinic (wax) content in

their base oils. Valvoline Gear Lube passed the test at 130,000 cP, only 13 percent lower than test limits.

| KRL Test Results | AMSOIL 75W-90 (After 192 hrs. KRL) |

Valvoline 75W-90 (After 20 hrs. KRL) |

| Beginning Viscosity @ 100°C (cSt) | 15.09 | 14.46 |

| Ending Viscosity @ 100°C (cSt) | 15.03 (pass) | 12.42 (fail) |

| % Viscosity Loss, 100°C | 0.40% | 14.10% |

1-37 High Torque Axle Test

Test Conditions

|

| The gears protected by AMSOIL 75W-90 Synthetic gear Oil showed little or no rippling, ridging, pitting or deposits following the L-37 High Torque Axle Test. |

The L-37 High Torque Axle Test is used to evaluate a gear lubricant's load-carrying, wear and extreme pressure characteristics in hypoid gears operating under both high-speed/low-torque and low-speed/high-torque conditions. A Dana Model 60 hypoid gear axle is used with either coated or uncoated drive gear and pinion to drive two dynamometers from an eight-cylinder, 5.7-liter gasoline engine. With the axle filled with the test lubricant, the high-speed/low-torque test is performed for 100 minutes, with the gears visually assessed afterwards. Next, the low-speed/high-torque test is run for 24 hours, followed by a thorough inspection of the gears. Performance relative to API GL-5 and MIL-PRF-2105E specifications is assessed based on tooth surface rippling, ridging, pitting and wear, deposits and discoloration.

Test Results

Testing on AMSOIL 75W-90 Synthetic Gear Oil was conducted using uncoated gears and pinions. The AMSOIL lubricant passed on all counts and showed little to no rippling, ridging, pitting or deposits, indicating that AMSOIL 75W-90 provides superior protection and performance under extreme pressure conditions.

L-42 High Speed Axle Test

Test Conditions

The L-42 High Speed Axle Test evaluates the antiscoring characteristics of a gear lubricant operating under high-speed and shock-loading conditions. A Spicer Model 44-1 hypoid gear axle is driven by a 5.7 liter, V8 gasoline engine with a four-speed truck transmission and two high-inertia dynamometers and hard accelerated to 100 mph. The axle is periodically shock-loaded through a dynamometer to simulate high shock-loading conditions. The axle is accelerated through the gears to 1,050 r/min and decelerated to 530 r/min. This cycle is repeated five times, followed by 10 shock loadings. In order to meet API GL-5 and MIL-PRF-2105E gear oil specifications, scoring must be equal to or better than gears tested with a reference oil.

Test Results

|

| The gears protected by AMSOIL 75W-90 Synthetic gear Oil showed little to no scoring following the L-42 High Speed Axle Test. |

AMSOIL 75W-90 Synthetic Gear Oil easily passed the L-42 High Speed Axle Test, receiving a significantly better rating than the reference oil and leaving little to no scoring on the ring and pinion.

| L-42 High Speed Axle Test | ||

| AMSOIL 75W-90 | Reference Oil | |

| Ring | 13 | 19 |

| Pinion | 18 | 27 |

We're now on Facebook!

Buy at wholesale price!

Preferred Customers buy at dealer cost and save 25%!

Not sure which products to get for your vehicle? Use the Vehicle Lookup Guide.

AMSOIL Distributor Opportunities

Start your own home business based on a proven superior product. Very low startup costs.

Sell AMSOIL products in your shop or store. Click here for information on AMSOIL retail accounts.

Does your business purchase lubricants for its equipment? Click for information about AMSOIL commercial accounts! Extend your equipment's life and reduce costs!